A research team led by Dr. Hyun-Ae Cha from the Korea Institute of Materials Science (KIMS) has developed a new composite material that excels in heat dissipation while being eco-friendly and cost-effective. The innovative material, inspired by egg whites, utilizes a unique protein foaming process to create a three-dimensional structure made from magnesium oxide (MgO). This structure significantly improves thermal conductivity, achieving levels up to 2.6 times higher than traditional heat-dissipating composites.

As electronic devices become increasingly powerful and compact, they generate more heat, necessitating effective thermal management systems. For electric vehicles (EVs), inadequate cooling of batteries can lead to reduced performance and potential safety hazards, including fires or explosions. At the heart of effective thermal management is the Thermal Interface Material (TIM), which is essential for efficient heat dissipation.

Traditional TIMs are produced by mixing thermally conductive fillers into a polymer matrix, but this often leads to random filler dispersion, disrupting thermal pathways and limiting performance. While increasing the filler content can enhance thermal conductivity, it also raises processing difficulties and costs, hindering scalability.

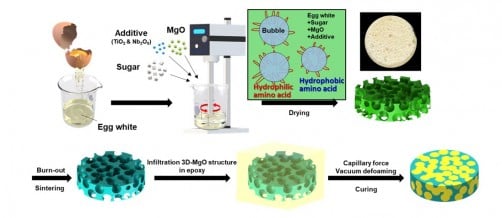

To overcome these limitations, the research team employed a protein foaming method that results in a densely interconnected structure of particles. The egg-white proteins expand when heated, enabling the formation of a three-dimensional network that maintains continuous thermal pathways. This breakthrough resulted in a thermal interface material with a thermal conductivity of 17.19 W/m·K, showcasing exceptional heat dissipation capabilities.

One of the key benefits of this material is its use of MgO, which is both lightweight and low-cost. The new composite outperforms commonly used aluminum oxide (Al2O3) and nitride-based heat-dissipating materials in terms of thermal conductivity. Additionally, by integrating the composite with epoxy resin—traditionally used with thermal fillers to improve adhesion—the team has created a practical solution for real-world applications.

This innovative technology is expected to enhance the performance and reliability of various high-heat-generating devices, including electronic equipment, semiconductor packages, EV batteries, 5G communication devices, and high-performance servers. The domestic market for TIMs in South Korea is projected to exceed KRW 200 billion annually, with a significant reliance on imports. The commercialization of this technology could bolster South Korea’s technological independence in thermal management materials.

Dr. Cha emphasized the environmental and economic advantages of their method, stating, “Through the protein foaming–based process, we can produce high–thermal–conductivity materials in an eco-friendly and cost-effective way.” She added, “This study serves as a strong example demonstrating the feasibility of developing lightweight, high-performance heat-dissipating materials.”

The research, funded by the National Research Foundation of Korea (NRF), was published in the prestigious journal Advanced Science on May 28, 2023, and was selected as the cover article for Volume 12, Issue 33.

This advancement represents a significant step forward in materials science, with broad implications for technology and sustainability in various industries.